| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | richly bound |

| Model Number : | High-strength aluminum composite panel |

| Certification : | ISO 9001:2008;GB/T 17748-2016;GB 8624-2012 |

| Price : | depends on your needs |

| Delivery Time : | usually within 14 working days |

| Payment Terms : | T/T |

PVDF ACP Sheet with 2.0mm Thickness, Solid Color, for Exterior Walls

Constructed from two distinctively different materials - metal and non-metal, the aluminum plastic board is a harmonious blend that both encapsulates the fundamental properties of metal aluminum and non-metal polyethylene plastic and transcends their limitations. It exhibits a plethora of superior attributes, such as opulence, dazzling color variations, weather endurance, resistance against corrosion and collision, fire and moisture protection, noise and heat isolation, and earthquake resistance. Its lightweight, ease of molding, and simple mobility and installment add to its advantages.

Product processing performance

The versatility of the aluminium composite panels that our company produces is exemplary, as they can be transformed and processed using typical woodworking and metalworking tools. Actions like cutting, sawing, milling, punching, pressing, folding, and bending can be flawlessly performed, ensuring the exact completion of an array of forms required by architectural decoration design. Especially for shapes such as arcs, counter-arcs, small-radius corners, and internal and external corners, the level of adaptability surpasses other decoration materials.

1. Cutting: Cutting tool, electric saw, hand saw, ring saw, etc.

2. Slot Milling: After processing with an electric and portable

slot milling machine, the product can be manually bent into various

kinds of polyhedrons.

3. Corner Removing: After processing with a puncher and corner

removing machine, it can be combined in a trunk.

4. Welding: The product can be welded with plastic welding rods and

hot wind welders.

5. Corner Bending: After processing with a slot milling machine,

the product can be bent into various corners.

6. Bending: The product can be bent using 3-point or 3-rolling

machines.

7. Printing: The product can be printed with screen printing

plates.

8. Assembling: Rivet, nail, self-tapping screw, etc.

9. Punching: The product can be punched with an open puncher.

Product Features

1. Uniquely Lightweight: Holds an excellent strength-to-weight

ratio. With uniform stiffness (E.j), the weight per unit surface

area of these aluminum composite panels is about 60% of aluminum

panels, and only 30% of steel panels.

2. Incredible Adhesive Strength: Features high 180° peeling

strength. There's no spontaneous peeling between the aluminum sheet

and the plastic core material, even after lengthy use.

3.Weather Tolerance: Exhibits virtually no change in color or gloss

with long-term outdoor use, with the coating remaining intact, and

the typical lifespan is over twenty years.

4.Anti-Corrosive Properties: The surface coating maintains strong

adhesion and can withstand the corrosion of acid (10%H2S04), alkali

(10%NaOH), and salt mist; the strength of the PVDF fluorocarbon

resin coating is notably superior.

5.Wind Load Resistance: Meets national A-grade criteria, satisfying

wind load resistance demands for high-rise building exterior

decoration.

6.Fire Resistant: The middle layer is composed of non-toxic

polyethylene, encased by non-combustible thin aluminum sheets on

both sides.

Our Company

Launched in 1999, we have excelled in producing Aluminum Composite Panels using cutting-edge equipment. Our panels, with their unique attributes, have left a mark on contemporary decoration trends. We are proud to be the first to receive the ISO 9001:2008 certification and have won numerous awards. Our primary brand, "Richly Bound", stands for our extensive range of quality offerings.

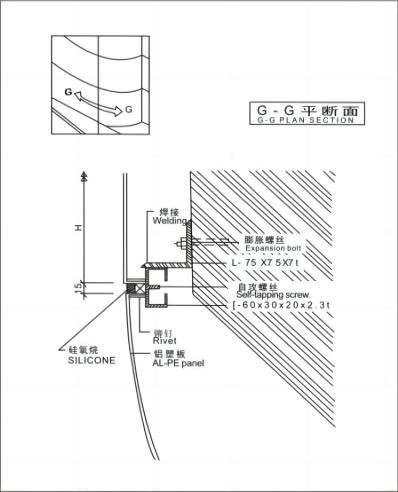

Product installation process diagram

|