| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | richly bound |

| Model Number : | A2 Fire Rated ACP Sheets |

| Certification : | ISO 9001:2008;GB/T 17748-2016;GB 8624-2012 |

| Price : | depends on your needs |

| Delivery Time : | usually within 14 working days |

| Payment Terms : | T/T |

3.0mm Fire Rated ACP Sheets with Mirror Finish, Customized Size, Aluminium Composite Panel

The aluminum plastic composite is a unique blend of two divergent materials - metal and non-metal, ingeniously synthesizing the optimal attributes of both. It retains the key characteristics of the original materials, such as aluminum and polyethylene plastic, and overcomes their shortcomings to realize a multitude of superior material properties. This includes its luxurious allure, vibrantly colorful decorativeness, weather resistance, corrosion resistance, impact resistance, fireproofing, dampness resistance, sound insulation, heat insulation, and seismic resistance. Additionally, it features a lightweight construction, ease of manipulation, and convenient transport and installation.

Product processability

The aluminum composite panels produced by our company can be processed and shaped using common woodworking and metalworking tools, including cutting, sawing, milling, punching, pressing, folding, and bending. This allows for accurate completion of various forms required by architectural decoration design, especially for shapes such as arcs, counter-arcs, small-radius corners, and internal and external corners. This level of versatility is unparalleled by other decoration materials.

1. Cutting: Cutting tool, electric saw, hand saw, ring saw, etc.

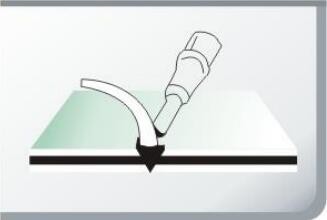

2. Slot Milling: After processing with an electric and portable

slot milling machine, the product can be manually bent into various

kinds of polyhedrons.

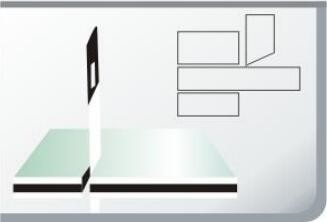

3. Corner Removing: After processing with a puncher and corner

removing machine, it can be combined in a trunk.

4. Welding: The product can be welded with plastic welding rods and

hot wind welders.

5. Corner Bending: After processing with a slot milling machine,

the product can be bent into various corners.

6. Bending: The product can be bent using 3-point or 3-rolling

machines.

7. Printing: The product can be printed with screen printing

plates.

8. Assembling: Rivet, nail, self-tapping screw, etc.

9. Punching: The product can be punched with an open puncher.

Product features

1. Light in Weight: Boasts an exceptional strength-to-weight ratio.

Given equal stiffness (E.j), the mass per unit surface of aluminum

composite panels is roughly 60% that of aluminum sheets, and just

30% of steel ones.

2. Robust Bond: Exhibits significant 180° peel strength. Over

extended use, there is no automatic separation between the aluminum

sheet and the plastic core material.

3. Durability in Various Weather: Demonstrates stable color and

gloss after prolonged outdoor exposure, with no flaking of the

coating and a general lifespan surpassing two decades.

4.Resilience to Corrosion: Its surface coating exhibits powerful

adhesion and can withstand the corrosive effects of acids

(10%H2S04), alkalis (10%NaOH), and saline fog; the PVDF

fluorocarbon resin coating is particularly robust.

5.Wind Load Endurance: Performance meets the national grade A

standard, catering to the wind load endurance needs of exterior

decoration for high-rise buildings.

6.Fire-Proof: The central layer is composed of non-toxic

polyethylene, sandwiched between two non-flammable thin aluminum

sheets.

About Us

Established in 1999, we have leveraged advanced continuous extrusion hot composite sheet production equipment for the manufacturing of premium Aluminum Composite Panels. Our products, offering remarkable features like fade and corrosion resistance, flame and moisture resistance, have revolutionized the modern decoration trends. We pride ourselves on being the first to pass the ISO 9001:2008 certification and have been acknowledged with various honors. Our "Richly Bound" brand signifies diverse, high-quality product offerings.

Processing Method

|