| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | richly bound |

| Model Number : | PVDF coating ACP Sheets |

| Certification : | ISO 9001:2008;GB/T 17748-2016;GB 8624-2012 |

| Price : | depends on your needs |

| Payment Terms : | T/T |

| Delivery Time : | usually within 14 working days |

PVDF ACP Sheets - 3.0mm Thickness, Special Effects Surface,

Anodized Coating, for Restaurant Interiors

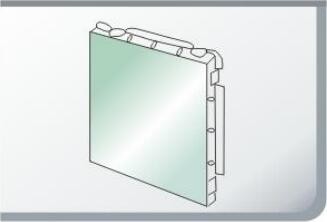

What's aluminum compsite panel?

Aluminum Composite Panel (ACP), commonly referred to as aluminum

plastic board, is a type of flat panel consisting of two thin

aluminum sheets bonded to a non-aluminum core. It is widely used in

building exteriors, interior decorations, and signage due to its

lightweight, durability, and versatility.

Aluminum Composite Panel (ACP), commonly referred to as aluminum

plastic board, is a type of flat panel consisting of two thin

aluminum sheets bonded to a non-aluminum core. It is widely used in

building exteriors, interior decorations, and signage due to its

lightweight, durability, and versatility.

The core material is often made of polyethylene or other fire-resistant materials, providing structural stability and thermal insulation. ACPs are popular for their aesthetic appeal, available in various colors, finishes, and patterns, including mirror, brushed, and wood grain surfaces. This combination of features makes ACP ideal for applications like cladding, facades, partitions, and advertising panels.

Our company—— Foshan Nanhai Huashi Decoration Material Ltd.

Foshan Nanhai Huashi Decoration Material Ltd.

Founded in 1999, we have imported top-tier extrusion equipment to

produce high-quality Aluminum Composite Panels. Our offerings

beautify exteriors of offices, malls, and high-rises, while also

enhancing interiors of luxury homes. Benefits include durability,

aesthetics, and insulation. Recognized with various awards, we've

also passed ISO 9001:2008 and are associated with key industry

bodies. Our "Richly Bound" brand offers diverse decorative panels.

We ensure quality, with products meeting national standards and

being recommended by authorities. Located near Hong Kong, we invite

global clients to collaborate.

Founded in 1999, we have imported top-tier extrusion equipment to

produce high-quality Aluminum Composite Panels. Our offerings

beautify exteriors of offices, malls, and high-rises, while also

enhancing interiors of luxury homes. Benefits include durability,

aesthetics, and insulation. Recognized with various awards, we've

also passed ISO 9001:2008 and are associated with key industry

bodies. Our "Richly Bound" brand offers diverse decorative panels.

We ensure quality, with products meeting national standards and

being recommended by authorities. Located near Hong Kong, we invite

global clients to collaborate.

What you can purchase

Here, you can purchase a wide variety of aluminum composite panels.

We offer 4mm thick PVDF-coated panels for exterior wall decoration,

3mm thick PE wood grain-coated panels for interior decoration, 4mm

thick A2 fire-resistant panels for interior passage wall

decoration, and more. We can even customize the product's

performance based on your specific needs.

We also offer a variety of colors for you to choose:

Why is ACP?

Aluminum composite panels (ACP) offer several advantages:

Lightweight and Durable: Despite being lightweight, ACPs are strong and durable, making them ideal for both interior and exterior applications.

Versatile Design Options: They come in a wide range of colors, finishes, and textures, including options that mimic natural materials like wood or stone, allowing for versatile design possibilities.

Weather Resistance: ACPs are highly resistant to weather elements, including UV rays, moisture, and temperature fluctuations, which helps maintain their appearance and integrity over time.

Fire Resistance: High-quality ACPs, especially those with fire-retardant cores, offer excellent fire resistance, enhancing the safety of buildings.

Easy Installation and Maintenance: The panels are easy to install and require minimal maintenance, reducing overall project costs and effort.

Cost-Effective: Compared to other cladding materials, ACPs are relatively cost-effective, offering good value for their durability and aesthetic appeal.

Sound and Heat Insulation: ACPs provide good insulation against sound and heat, contributing to the energy efficiency and comfort of buildings.

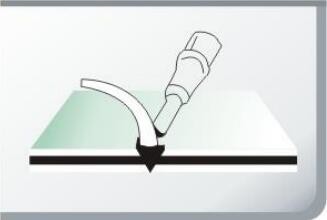

Product processing performance

Our aluminum composite panels can be easily processed using both woodworking and metalworking tools, allowing for various operations such as cutting, sectioning, milling, perforating, compressing, folding, and bending. This enables precise fulfillment of architectural decorative needs, including designs like curves, reverse curves, small-radius bends, and both internal and external angles. Such versatility is uncommon in other decorative materials.

print corner bending corner cutting welding

corpping punching bending milling groove

combination

Our production line

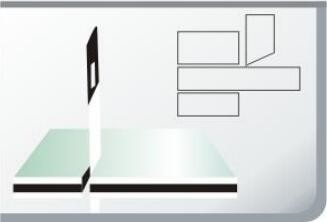

Illustration of on-site construction and installation methods

|